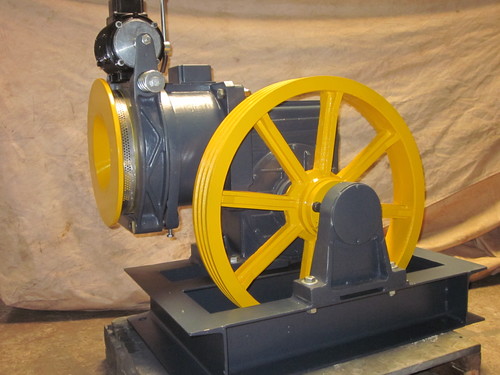

Product Description

We have become a dominant player in the market of manufacturing and supplying Geared Traction Elevator. The gearbox attached to the motor that is used to operate the wheel and thus move the ropes. To manufacture this elevator motor, we use optimum quality cast iron. It is able to travel at speeds of 500 feet per minute, with a minimum travel distance of 250 feet. Geared Traction Elevator is available in different power specifications as per client's requirements.

Features:

- Robust construction

- Easy installation

- Less noise generation

H.P | 5 |

Size | 127 mm |

RPM | 960 |

Technical Specifications

Size | Ratio | H.P | RPM | Pulley (Dia) | Speed m/Sec. | Passenger | Height (in meters) |

127 mm | 01:40:00 AM | 5 | 960 | 510 mm | 0.64 | 6 | G + 6 |

127 mm | 01:40:00 AM | 5 | 960 | 530 mm | 0.66 | 6 | G + 5 |

140 mm | 01:44:00 AM | 6 | 960 | 510 mm | 0.58 | 8 | G + 7 |

140 mm | 01:44:00 AM | 6 | 960 | 530 mm | 0.6 | 8 | G + 6 |

140 mm | 01:44:00 AM | 6 | 960 | 560 mm | 0.64 | 8 | G + 5 |

Built for Performance and SafetyThis elevator series blends reliable geared traction technology with rigorous safety features, including an overspeed governor, emergency alarm, and rescue device. It offers smooth rides and low noise levels below 65 dB, suitable for diverse climates ranging from -10C to 40C. Smart microprocessor or PLC controls enhance responsiveness and ensure all operations are monitored.

Customizable FlexibilitySupporting up to 24 stops with a maximum lifting height of 80 meters, our elevators are tailored by cabin size, load, and interior finish. Door openings range between 700 and 900 mm, with compact hoist way and machine room footprints. With load capacities up to 2000 kg, applications range from small apartment blocks to large-scale commercial complexes.

Energy Efficient Modern ControlsOutfitted with VFD (Variable Frequency Drive) controls and energy-saving LED lights, the system prioritizes efficiency and low operational costs. The elevator features an automatic rescue device to ensure safety during power interruptions, providing peace of mind for building occupants while reducing the carbon footprint.

FAQs of Geared Traction Elevator:

Q: How does a geared traction elevator with an overhead machine room operate?

A: This elevator utilizes a geared traction drive system, where an electric motor and gearbox are located in a machine room above the elevator shaft. The motor drives ropes connected to the elevator car and counterweight, providing smooth, efficient, and reliable vertical transportation, controlled via a microprocessor or PLC-based system with VFD for speed regulation.

Q: What are the benefits of VFD (Variable Frequency Drive) control in this elevator?

A: VFD technology allows for precise speed regulation, smooth acceleration, and deceleration, reducing power consumption and mechanical wear. It also improves ride comfort and extends the lifespan of both the elevator and its components, contributing to quieter and energy-efficient operation.

Q: When should the automatic rescue device (ARD) in the elevator be used?

A: The automatic rescue device (ARD) activates during power failures. It safely moves the elevator car to the nearest floor, allowing passengers to exit without assistance. This essential emergency feature ensures occupant safety and minimizes entrapment risks in case of unexpected outages.

Q: Where is the machine room typically located for this elevator model?

A: For this geared traction elevator, the machine room is situated directly above the elevator shaft. Standard dimensions are approximately 2000 x 3000 mm, providing easy access for maintenance while optimizing shaft space for the car and counterweight mechanisms.

Q: What options are available for cabin finish, door type, and display?

A: Cabins can be finished in hairline stainless steel or painted mild steel, chosen for durability and aesthetics. Door options include automatic center opening or telescopic styles. Floor positions are displayed on either a digital or LCD indicator, enhancing user convenience and clarity.

Q: How can the elevator be customized for specific building needs?

A: Customization options include cabin dimensions, car load capacity (320 to 1500 kg), door opening size (700900 mm), and interior accessories such as intercom, mirror, handrails, and ventilation fans. Hoist way and pit dimensions are adjusted based on the required capacity and car size to suit building constraints.

Q: What safety standards does this elevator comply with?

A: This elevator adheres to IS 14665, EN81-1, and CE standards, ensuring comprehensive safety through mechanisms like an overspeed governor, safety gear, door locks, buffers, and emergency alarms, providing reliable protection for both passengers and cargo.